The oil and gas industry is one of the most critical industries globally, and remote monitoring and control of oil wells are essential to increase productivity and ensure safety. However, traditional monitoring systems often face challenges such as poor connectivity, high cost, and low reliability. To overcome these challenges, the application of advanced 4G industrial gateway technology, such as the ZR3000, has emerged as a viable solution.

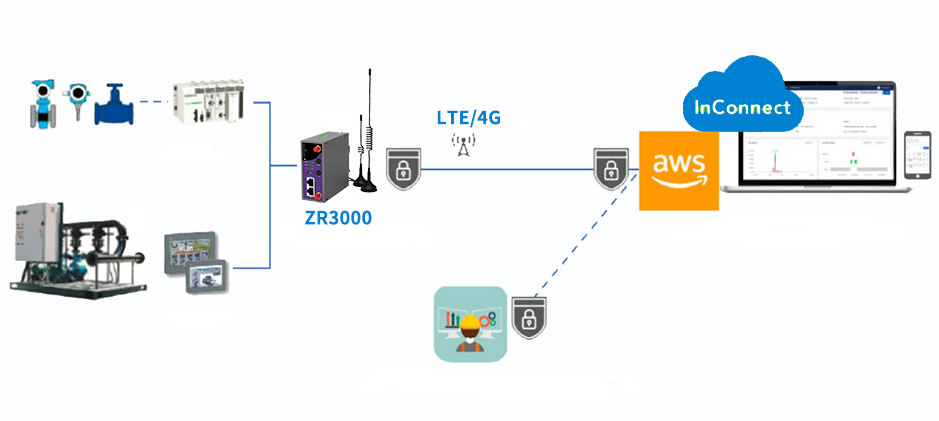

The ZR3000 4G industrial gateway can provide a reliable, secure and cost-effective communication link between the wellsite and remote control centers. It can be deployed in various locations and supports multiple connectivity options such as Ethernet, Wi-Fi, and VPN. The dual SIM card slots ensure high availability and reliability of the internet connection, even in areas with poor connectivity. The gateway’s failover/failback feature enables automatic switch-over to the backup connection in case of a primary connection failure, ensuring uninterrupted communication.

The ZR3000 4G industrial gateway’s remote maintenance and troubleshooting feature enables technicians to remotely access and diagnose equipment issues, reducing travel time and costs. It also enables remote firmware updates and configuration changes, enhancing system flexibility and reducing downtime.

In terms of remote control, the ZR3000 4G industrial gateway allows for the remote monitoring and control of critical variables such as pressure, temperature, and flow rate. The gateway can send commands to the wellsite to adjust the pressure or open/close valves, among other things, ensuring timely intervention in case of any issues.

Overall, the application of ZR3000 4G industrial gateways in remotely controlling oil wells addresses the pain points of poor connectivity, high costs, and low reliability, ensuring safe, efficient, and productive oil and gas operations.